Dear valued customer:

Welcome to our new website. It will be the new gateway for BOOTS. On top right hand side of the page are your login boxes. Please use your username and password and the site will take you to BOOTS.

Note that we are also updating BOOTS to be compatible with the latest server OS and this will be launched shortly. Thank you for your cooperation.

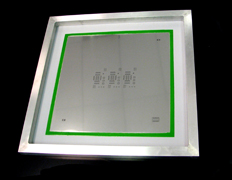

Framed stencils are unsurpassed for use in production runs where stencil performance is critical. Foils are stretched with specially designed polyester mesh attached to a rigid aluminum frame. This guarantees absolute flatness and allows for superb printing results from the first print to the last.

We offer framed stencils in the two most common sizes, 29”x29” and 20”x20”. Other frame sizes are available by request, including Fuji, Panasonic, and several solid aluminum cast frames. We also offer electropolishing and nano treatment, proven to enhance paste release for printing fine openings with area ratios of 0.60 and below.

Mounting a stencil on a meshed frame

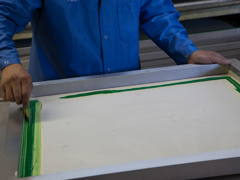

Order papework is reviewed and the proper frame type and epoxy color is chosen. The foil is then carefully positioned on a frame prestretched with high tension polyester mesh. It is then secured to the mesh with mask.

A border on the printing side of the stencil is created with mask and epoxy is carefully applied within this border. An experienced hand makes it look easy, but proper glue application is critical to the integrity of the bond.

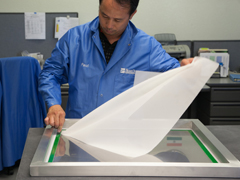

After applying the glue the stencil is placed on a hot table and cured until the mesh is properly bonded to the foil. The center mesh area is then cut away transferring force to the foil perimeter and achieving the flatness and tension framed stencils are known for.