Dear valued customer:

Welcome to our new website. It will be the new gateway for BOOTS. On top right hand side of the page are your login boxes. Please use your username and password and the site will take you to BOOTS.

Note that we are also updating BOOTS to be compatible with the latest server OS and this will be launched shortly. Thank you for your cooperation.

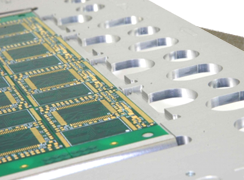

The most basic class of assembly fixtures are used from the smallest CM’s to the large tier 1 houses. At their most basic, they allow you to move your assembly through your process.

Why do customers use us then?

In one word, design. Beam On creates fixtures that reflect two decades of experience and feedback from our customers. We strive to minimize costs to our customers by keeping fixture size and thickness minimal and by adjusting the design to accommodate both primary and secondary side process. Since Beam On also designs SMT stencils we intuitively add clearances for thermal transfer to prevent cold solder and add fiducials to the fixture when the board is designed without them. We are also very familiar with flex board assemblies whether in single or panel format. By utilizing our design experience and knowledge we can streamline the ordering process and allow our customers to use their time more efficiently.

Process Considerations When Ordering

Pick and Place |

Reflow |

|

| No surface features such as clamps or bars above PCB surface height | If not used for printing, clamps are recommended to prevent vibration | No materials allowed that cannot withstand reflow temperatures |

| Large PCB’s need adequate support but consideration for parts a must | Inadequate board support may cause the PCB to “bounce” during placement | Material underneath critical parts such as BGA’s and fine pitch should be removed for thermal transfer |

| Thin PCB’s may require low profile clamping or “draw” type pins | Skybars can be used to help hold down connectors which suffer coplanarity issues during reflow | |

| Irregular shaped PCB’s can use the same fixture, but an offset may be required which can affect the stencil | Holes can be drilled in the fixture to reduce thermal mass and assist reflow | |

| For PCB’s without adequate fiducials small pins are to be added to both fixtures and stencil |

Materials Considerations When Ordering

| 4mm Durostone is recommended for PCB’s with standard .062” thicknesses. For large boards 5mm or greater may be needed for adequate support | For some applications, aluminum is recommended for it’s ability to maintain sharp clean edges for thin fitted flex boards. Also it can be an adequate lower cost alternative. |

| Durostone comes in 3 grades Gray, black, and blue. Gray and black are ESD while blue is not. The most commonly used material is black, but premium gray can be substituted. | You should decide on material thickness starting with thinner material then move up in thickness as needed. This will aid in reducing thermal mass and keep fixture cost down. |

| We can mark fixtures for RoHS process but you must specify this during ordering. | We also carry other composite type material such as G10 but we recommend Durostone for it’s flatness and uniformity |

| You can save money by understanding that SMT Transport, 5dx or Xray, and sometimes Point to Point Solder fixtures are often the same fixture by removing or adding the clamps | Not only can you save time by ordering both fixtures AND stencils through us, but we automatically try to design for both top and bottom on one fixture as well as adding fiducials when needed |